The microstructure of the duplex stainless steel globe valve consists of a mixture of an austenitic phase and a ferrite phase. Therefore, the duplex steel has both austenitic and ferritic stainless steel properties.

The duplex globe valve uses stainless steel which has stronger resistance to corrosion than the commonly used grades of stainless steel valves, namely 304 valves and 316 valves. Duplex stainless steel valves are widely used in various industries such as the chemical industry, seawater desalination, shipbuilding, petrochemical industry, oil, and gas industry.

Pharmaceutical Equipment

Chemical Equipment

Sea Water Equipment

Heat Exchangers

Condensers

Pulp and Paper Industry

Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

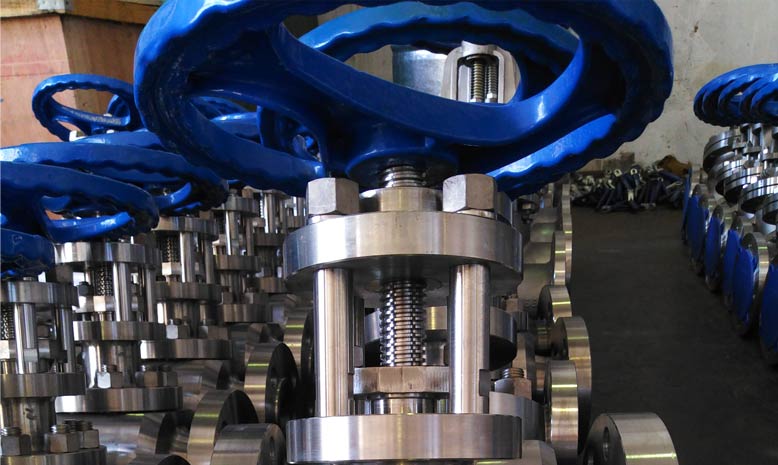

Cast steel duplex globe valve is an excellent valve to use for shut-off service and shall be installed in the proper direction as flow arrow marked in the body. Unless other specific, globe valve shall be used for uni-directional seal.

Duplex materials are always available with S31803(F51), S32750(F53), S32760(F53), S32205(F60), S32550(F61) etc with relevant casting code ASTM A890/A995 1A, 2A, 3A, 4A, 5A, 6A, 1B, 1C, CD4MCu, CD4CuN, CD3MCuN, CE8MN, CD6MN, CD3MN, CE3MN, CD3MWCuN.

With a simple structure, duplex globe valves can be manufactured easily.

It is convenient to maintain the surface and property of a duplex globe valve.

The duplex globe valve has greater corrosion resistance in stress corrosion cracking.

At a rather lower price, duplex globe valves have low friction between the sealing surface and long life.